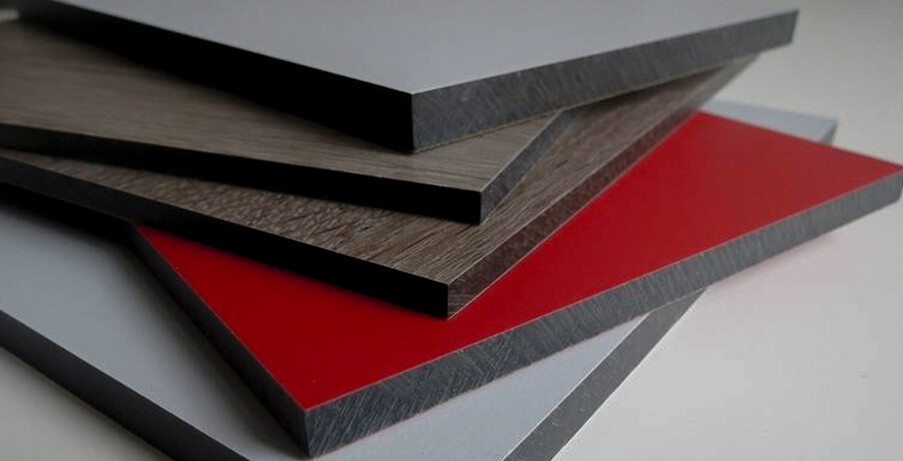

HPL plastic

New materials appear on the construction and furniture market all the time. Modern manufacturing technologies give materials new properties and characteristics: increased strength, resistance to damage, durability, authenticity of imitation of natural materials. One of these new products is HPL plastic.

What is HPL plastic

HPL (High Pressure Laminate) is a high pressure plastic - a modern composite material obtained from paper sheets, thermoactive resins and a protective layer. At first, this versatile facing material became popular in Europe, now it has become widespread in Russia, where it is widely used in furniture production and construction. We also call it DBSP - decorative paper-laminated plastic.

HPL sheet consists of 3 layers:

- Kraft paper impregnated with a thermoplastic resin that contains phenols. Additional components can be added to make the fire retardant and postformable.

- A decorative paper layer that defines the appearance of the plastic. It can be monochrome or imitate natural materials (wood, stone, metal).

- Protective coating (overlay). Thanks to him, the plastic has a high resistance to aggressive environments, ultraviolet radiation, mechanical stress.

The HPL sheet is very dense. Thickness from 0.5mm to 2.5cm is determined by the number of sheets of kraft paper. There are practically no pores in the structure, therefore the surfaces are applicable in medicine - they are easy to clean, food particles, dust particles do not linger in them, microbes do not develop.

HPL technology

HPL is made from paper impregnated with polymer resins. Under the influence of high pressure and temperature, the resinous substances melt, evenly fill the pores of the paper fibers, glue the sheets together and harden.

The finished product acquires strength, solidity, becomes resistant to mechanical stress, humidity and temperature.

In the production of decorative HPL plastic, an additional decorative layer is used (for self-supporting panels - 2 layers on both sides). With the help of a press plate, it is given the necessary texture. A large selection of embossing combined with a variety of colors allows you to get more than 3000 unique surfaces.

Advantages of HPL plastic

Thanks to a special production technology and the use of a special protective coating, decorative paper-laminated plastic has a number of properties that make it a truly universal finishing material:

- High strength.

- Resistant to scratches, dents and impact chips.

- UV resistant.

- Environmental friendliness - do not emit harmful substances into the air.

- Fire resistance.

- Ample opportunities for design.

- Plastic bends, so not only straight structures are made of it, but also rounded.

You can get a wood or stone design, indistinguishable from natural, while HPL panels are lightweight, are not afraid of water, high temperature, steam, have a relatively low cost, and last longer.

Types of HPL plastics

There are the following types of high pressure LBSP:

- Flame retardants are classified as KM-1 fire hazard class.

- Postformable plastic. It can be given curved shapes.

- For clean rooms - they are characterized by high chemical resistance and antibacterial properties.

- For facades - special fire-fighting properties, resistance to weathering and ultraviolet radiation.

- The standard is used as a decorative coating or as an independent supporting structure.

- Compact - engineering plastic with a thickness of up to 25 mm and a decorative coating on both sides.

Application

Due to their versatility, strength and decorative qualities, HPL panels are in demand in the manufacture of furniture, interior decoration and building facades.

They can be used in bathrooms, shower rooms, lavatories, for the production of self-supporting partitions, wall cladding.

На кухне их применяют для изготовления столешниц. При этом выбирают пластик, который можно подвергать постформингу. Также из пластика делают стеновые панели для фартука, мебельные фасады для кухонного гарнитура.

HPL is an excellent solution for clean rooms in medicine, pharmaceutical, chemical and other industries. Microorganisms practically do not multiply on such a surface. It can be washed with aggressive chemicals, and the appearance of the coating will not be affected by this.

High resistance to ultraviolet rays, impacts, scratches, durability allow the use of paper-laminated plastic for exterior decoration of buildings. HPL panels are used in the construction of ventilated facades, finishing gables, balconies, plinths, entrance lobby. Also, the material is chosen for the manufacture of fences, awnings, outdoor furniture and various decor.

For offices, shopping centers, cafes, restaurants, partitions, furniture, and wall panels are made from wood-fiber boards. Used for surface cladding in transport.

A wide range of colors, reliability and durability of the cladding make HPL plastic a unique material. It is suitable for residential and non-residential buildings, exterior and interior surfaces.