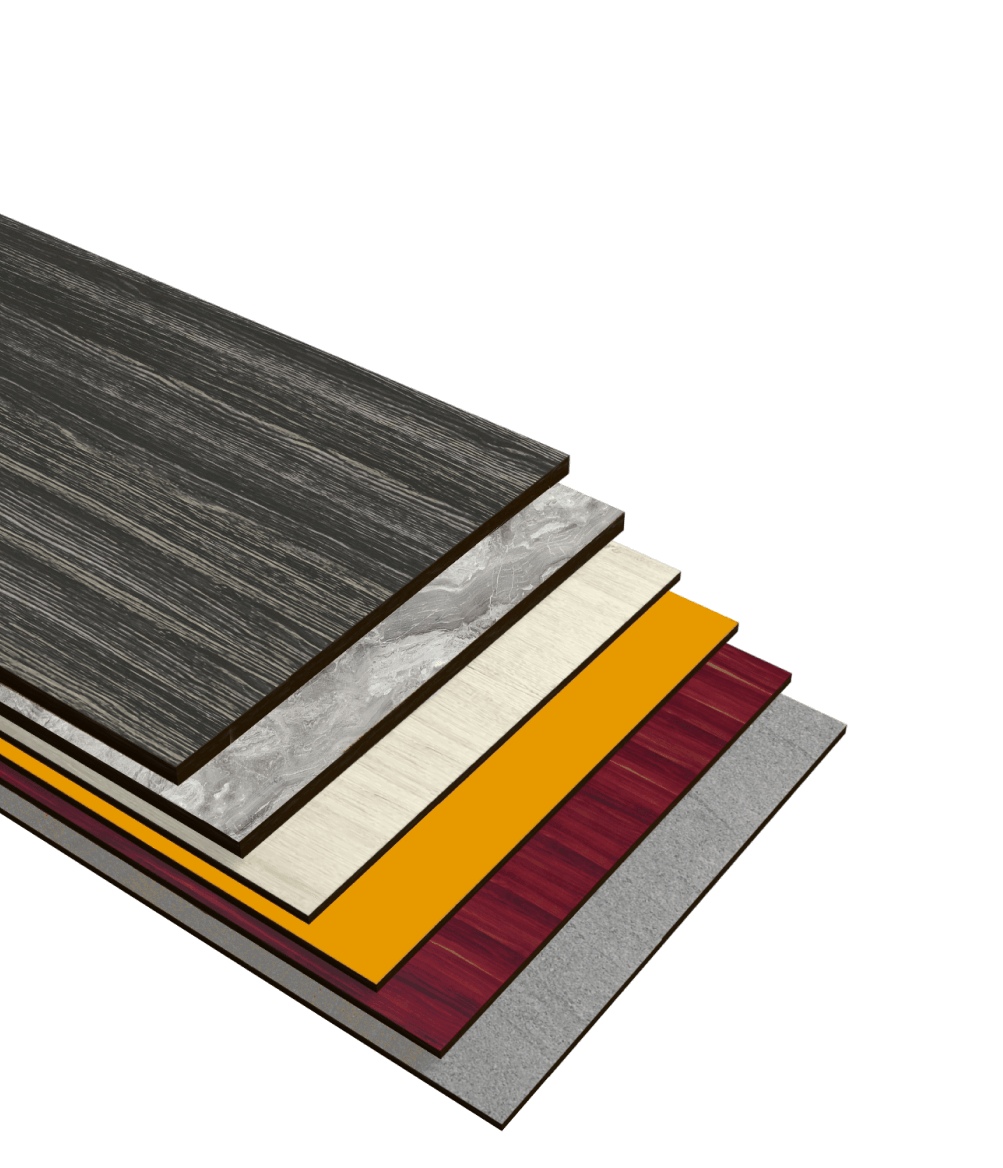

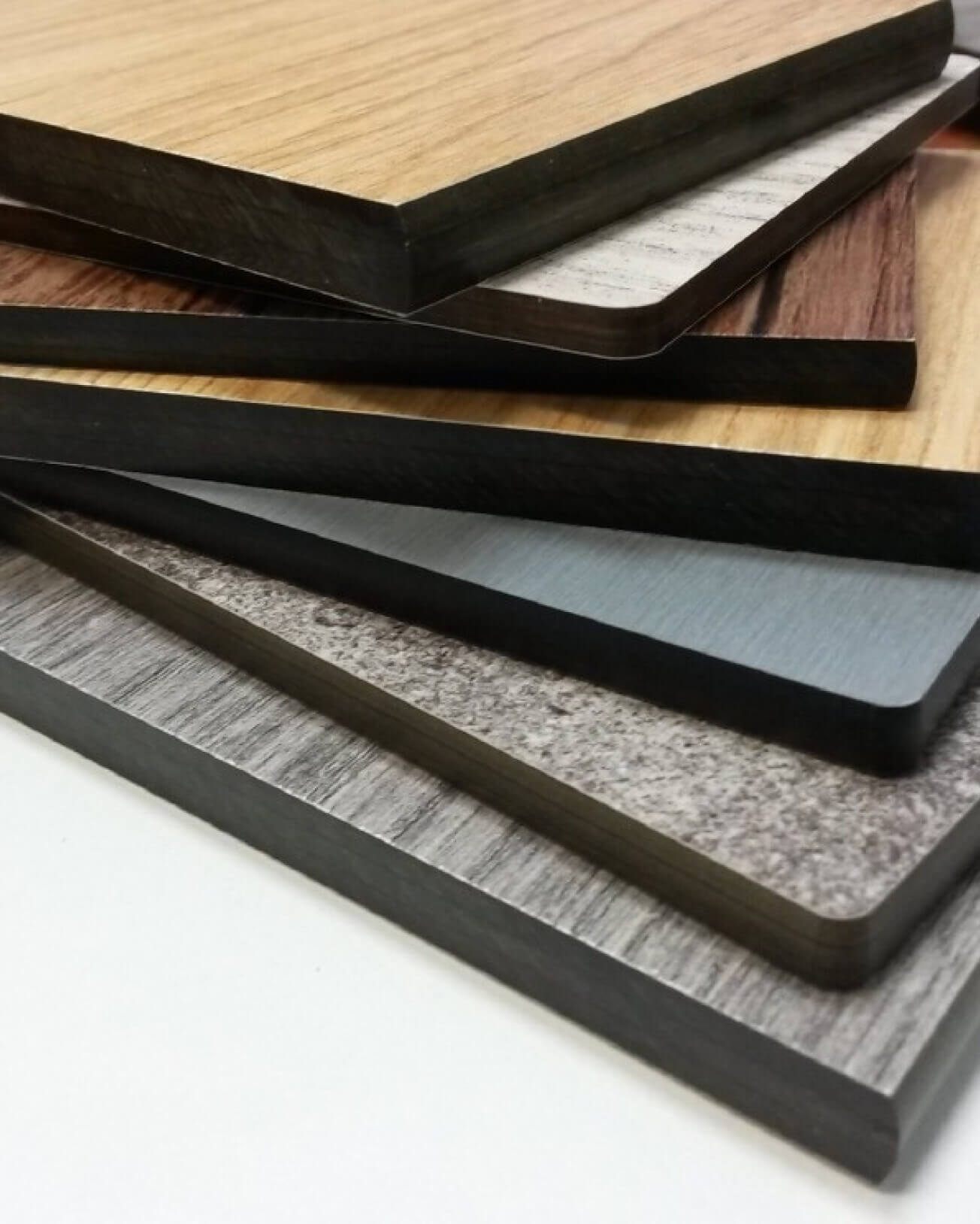

Decors

The Lemark range includes finishes that artfully convey the beauty of natural wood, stone, and metal, and solid colors are perfect for creating a modern room style.

A variety of decors will delight the most demanding customers and open up wide opportunities for implementing any design ideas.

-

01

01Plain

-

02

02Woody

-

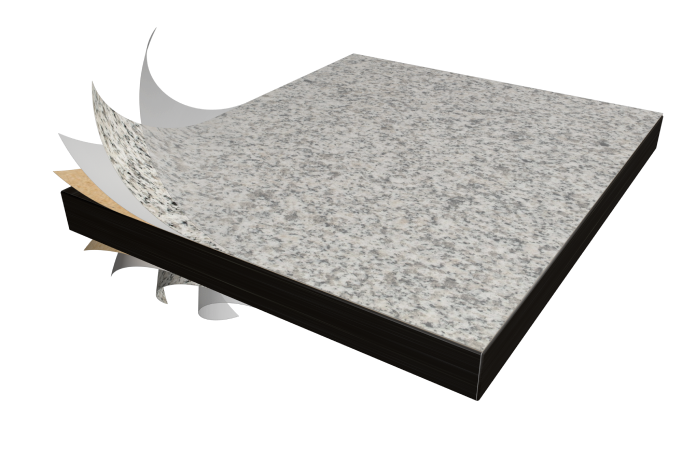

03

03Stone

-

04

04Fantasy

-

05

05Metallized