HPL panels for construction

-

Up to 20% benefit from full-cycle production

-

3156 unique surfaces

-

Fire resistance class KM1

-

Production time is up to 14 days

New technologies are increasingly being used in the construction industry. Now the main priorities in the choice of materials are high performance, affordable prices, and aesthetic appearance. So HPL panels have become one of the most popular materials for facade cladding and interior decoration. HPL laminated plastic is a modern construction and finishing material with many unique properties. It is used in the construction industry, the manufacture of playgrounds, furniture, small architectural forms, finishing of "clean rooms" and many other industries.

HPL Lemark panels are the choice of those who are not ready to overpay but appreciate the high quality and speed of order receipt. Laminated plastic has successfully passed numerous tests, which is confirmed by the relevant certificates.

Application of Lemark laminated plastic

Lemark plastic advantages

Wear resistance and durability

HPL panels are resistant to mechanical damage, scratches, and chipping due to their ultra-dense monolithic structure. The material retains its original properties and aesthetic appearance over many years of active use.

Protection against temperature changes

One of the main advantages of Lemark HPL panels is their resistance to any weather events. They are not afraid of temperature changes, frosts, rain, and snow. The operating temperature range is from +70°C to -50°C, which allows the material to be used even in the Far North

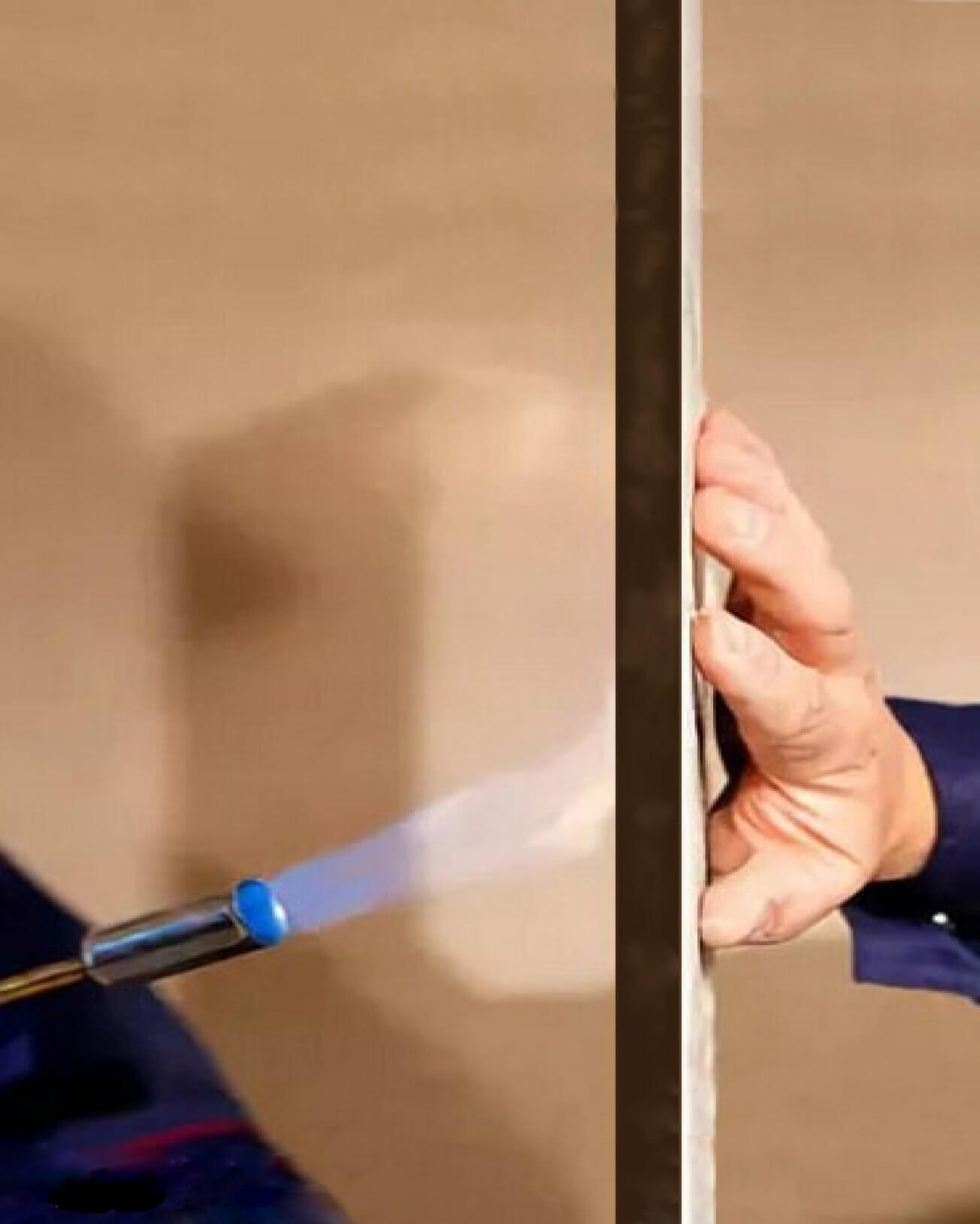

Fire resistance

Hard-to-burn HPL panels are not subject to combustion and do not emit harmful substances at elevated temperatures, which is confirmed by the KM-1 fire safety certificate with a full test report

Eco-friendly

Decorative laminated plastic is harmless to humans and the environment. HPL Lemark meets sanitary and epidemiological requirements, which are confirmed by certificates. It is recommended for use in medical and educational institutions.

Ease of installation

Installation of HPL panels for facades can be carried out at any time of the year. Due to its low weight, the material is simple and easy to install. Laminated plastic is excellent for cladding not only new buildings, but also the reconstruction of old ones that are not designed for heavy loads.

UV resistance

In the production of laminated plastics, we use special protective coatings. Thanks to them, the material becomes resistant to ultraviolet radiation and retains an attractive appearance throughout its entire service life.

Maximum moisture resistance

Due to the monolithic structure and the absence of pores, layered plastics do not absorb moisture. The material is invulnerable to the formation of fungi, mold, rot, and other micro-organisms.

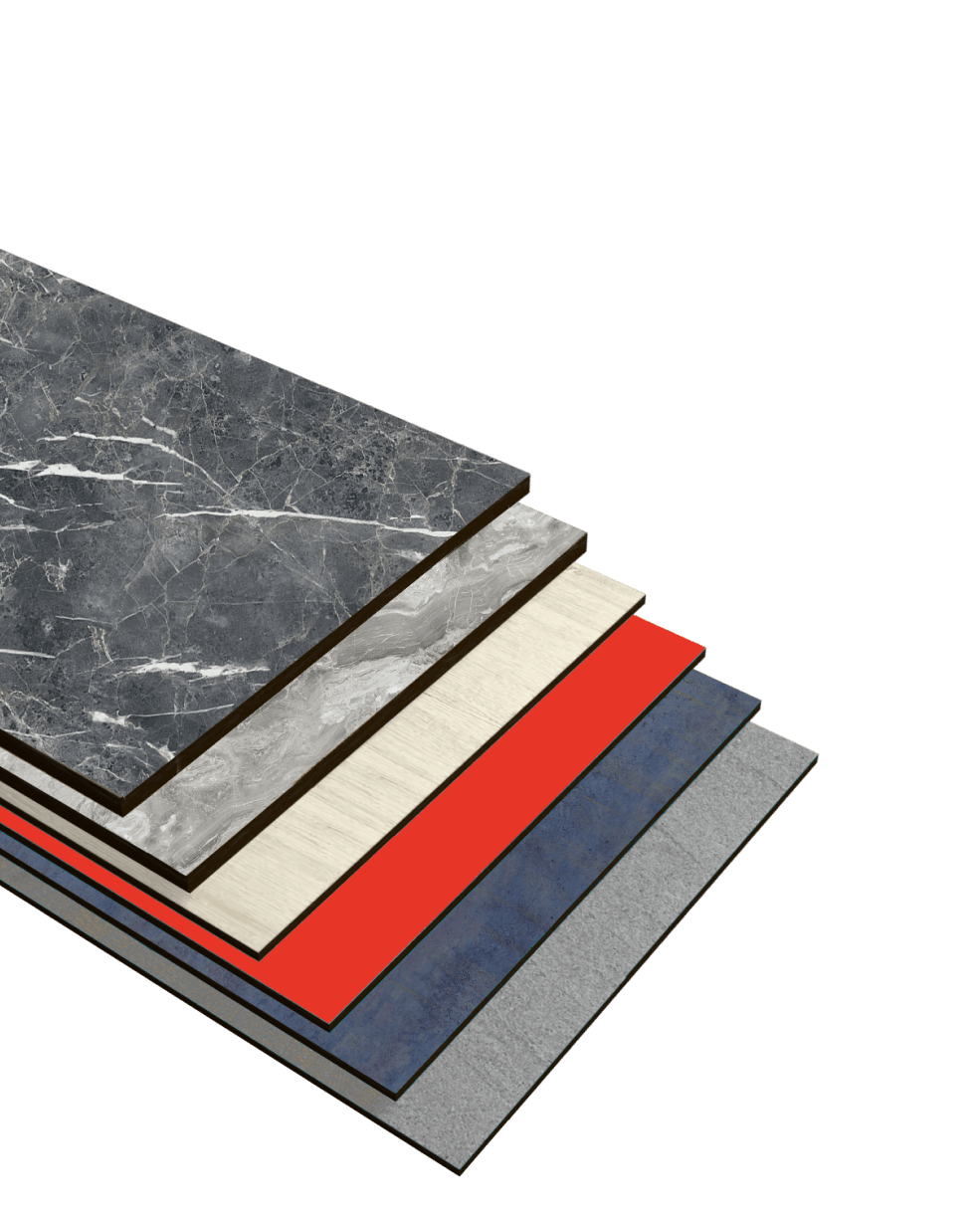

Variety of decors

The Lemark factory produces over 250 types of decors (solid, wood, stone, metallic, fancy, etc.), 12 types of embossing allow architects and designers to embody bold and creative ideas.

FORMATS AND SIZES

TECHNICAL INFORMATION

Applying HPL plastic requires certain knowledge and skills. Our recommendations and technical solutions will help you complete the installation of HPL panels efficiently and quickly.

anywhere in the Russian Federation and the CIS!

KINDS

-

Standard (ST)

It is used for facing smooth (flat) surfaces. It can be either one-sided (thickness from 0.6 to 2.0 mm) or two-sided structural material (thickness from 4.0 to 25.0 mm)

-

Hard-to-burn (FR)

It is produced by the requirements of Federal Law No. 123 and belongs to the fire hazard class KM-1, which is confirmed by the certificate. Plastic thickness from 0.6 mm to 25 mm.

-

Facade (EG)

Laminated plastic for exterior decoration of buildings and structures, has high fire-fighting characteristics, resistance to external aggressive environment, and ultraviolet (UV).

-

Lab (LG)

Laboratory (chemically resistant) plastic is produced specifically for surfaces where chemicals and reagents are used. This material is produced in thickness from 0.6 mm to 25 mm.

-

Biocidal (CR)

Medical plastic with antibacterial properties, which is widely used in" clean " rooms. Prevents the formation of fungi, mold, and other microorganisms. Produced in thickness from 0.6 mm to 25 mm

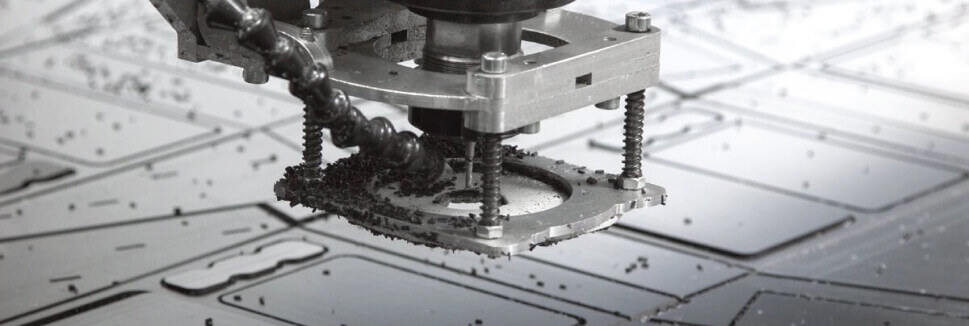

HPL plastic processing

-

01

We have been engaged in the processing of laminated plastic for more than ten years. During this time, we have completed more than 250,000 orders.

-

02

The high qualification, an extensive set of knowledge, and many years of professional experience guarantee an impeccable order quality.

-

03

We use modern high-tech CNC machines. The precision of the CNC router of the machine is 0.01 mm, which guarantees the quality of processing.

-

04

Own production and the absence of intermediaries ensure transparency of calculation and low prices.

You can buy custom HPL panels from Lemark. For consultation, price calculation and production time

plastic fill out the form.

We will contact you within 10 minutes.